Why Specify the V-3.5, V-5, V-8 anchor on Your University, Church, Government, Historic Renovation or Multi-Family Residential Project?

Five Reasons Architects are Specifying V-Series Permanent Anchors:

1. Falls are the leading cause of injury and death at the workplace and OSHA requires fall protection systems for any exposures greater than six feet to a lower level.

2. Architects understand that buildings/roofs need maintenance and workers need safe working conditions. Designing fall protection systems into buildings is now common practice in the architectural design and construction industry. Fall protection systems are regularly implemented into flat roof projects. It is logical to design them into steep roof projects as well (where the worker relies on ropes and anchors to protect their lives).

3. Failure to design and install OSHA compliant fall arrest systems creates additional hazards for all workers on the roof and exposes building owners to unnecessary liability risks.

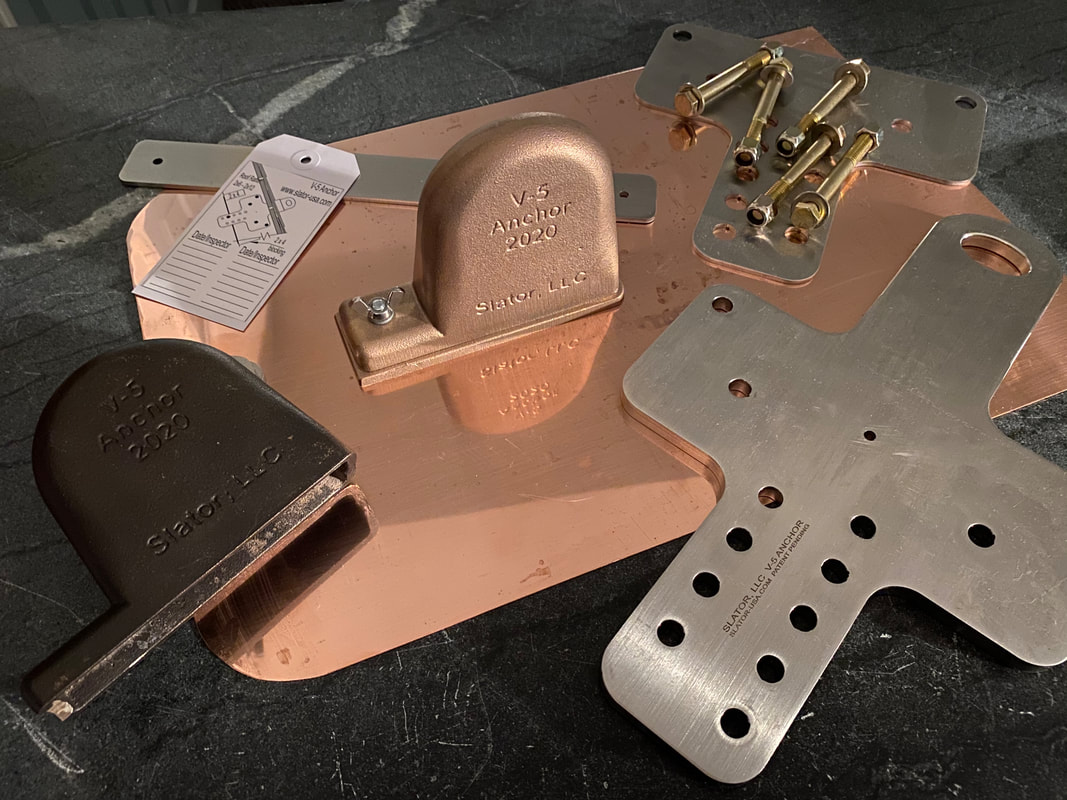

4. The OSHA compliant V-Series permanent anchors are low profile, covered with a bronze cap, and blend easily into finished roofs so they become unnoticeable. They are easily compatible with historic slate, copper, tile, or today's asphalt shingle roofs.

5. The unique design of the V-Series permanent anchors allows the periodic mandatory inspections (as required by OSHA) to be performed from the safety and convenience of the attic. This saves the building owner money annually, while also reducing risk. Most permanent anchors on the market require the inspector to climb onto the roof. This practice is time consuming (expensive), creates additional wear and tear on the roof, exposes inspectors to fall hazards, and exposes those below to potential dropped objects.

2. Architects understand that buildings/roofs need maintenance and workers need safe working conditions. Designing fall protection systems into buildings is now common practice in the architectural design and construction industry. Fall protection systems are regularly implemented into flat roof projects. It is logical to design them into steep roof projects as well (where the worker relies on ropes and anchors to protect their lives).

3. Failure to design and install OSHA compliant fall arrest systems creates additional hazards for all workers on the roof and exposes building owners to unnecessary liability risks.

4. The OSHA compliant V-Series permanent anchors are low profile, covered with a bronze cap, and blend easily into finished roofs so they become unnoticeable. They are easily compatible with historic slate, copper, tile, or today's asphalt shingle roofs.

5. The unique design of the V-Series permanent anchors allows the periodic mandatory inspections (as required by OSHA) to be performed from the safety and convenience of the attic. This saves the building owner money annually, while also reducing risk. Most permanent anchors on the market require the inspector to climb onto the roof. This practice is time consuming (expensive), creates additional wear and tear on the roof, exposes inspectors to fall hazards, and exposes those below to potential dropped objects.

|

Residential:

|

Commercial Clients:

The commercial clients we service are generally intelligent, careful, and forward thinking. They understand that employee safety is a top priority and require OSHA compliant fall protection 100% of the time while their roofs are being serviced. They also understand that the law requires every employee who is exposed to a potential fall of 6' or greater be protected with a fall protection system. They agree that the long-term benefits of permanent fall protection anchors greatly offset the initial up front expense. They are long-term thinkers and understand the following facts:

|

Our customized patent-pending V-5 permanent roof anchor is a massive 3/8" - 1/2" thick stainless steel plate. With no moving parts or welds to fail, the V-5 is easily fully inspectable from the safety of the attic and is a preferred anchor system by architects and property owners. Similar to an iceberg, the huge bulk is beneath the surface. It wraps completely around the roof rafter and comes in sizes to fit 2x6 to 2x12 rafters or customized to be compatible with other roof systems. Outfitted with the discreet cast bronze and copper flashing kit shown above, it's designed to be practically unnoticeable and service workers for the life of the building.

Once installed on a building, forevermore . . . climb up, clip in, and get right to work, safely.