The plumbing stack on a slate roof should be unnoticeable, not leave white lead streaks running down the roof, be completely maintenance free, last the lifetime of the slate, and NEVER LEAK. It should be made so that all future remodeling is simple.

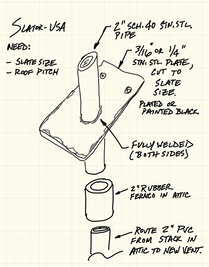

A remodeling job a few years ago inspired this creative solution for plumbing vents and we are happy to help you as well if you ask. Our design requires more work up front, but then installs just like a piece of slate and requires no flashing. It is a maintenance free, lifetime solution that also looks attractive and blends in with the roof. It is now our standard practice in our slate roofing business.

Basically, the plumber has forever decided where vent stacks are placed. Well, that made sense 100 years ago when working with heavy cast iron pipes, but that should no longer be the case. PVC is used throughout buildings in all new construction and remodels. All cast iron will eventually be replaced. Of course, over the last hundred years the flashing rusts, leaks or copper wraps get condensation between the old pipe and the copper (which drips into the attic). Anyway, there are many problems with the "current" methods of dealing with plumbing vents. So, our standard practice has evolved into cutting the stack in the attic and moving the vent to a desirable location. Scroll down below the pictures to continue reading.

Basically, the plumber has forever decided where vent stacks are placed. Well, that made sense 100 years ago when working with heavy cast iron pipes, but that should no longer be the case. PVC is used throughout buildings in all new construction and remodels. All cast iron will eventually be replaced. Of course, over the last hundred years the flashing rusts, leaks or copper wraps get condensation between the old pipe and the copper (which drips into the attic). Anyway, there are many problems with the "current" methods of dealing with plumbing vents. So, our standard practice has evolved into cutting the stack in the attic and moving the vent to a desirable location. Scroll down below the pictures to continue reading.

IT'S AS SIMPLE AS 1,2,3.

1. Install the new vent stack stub in your desired location (just like a piece of slate).

2. Cut out the old cast iron stack in the attic. Fix any rotten boards as necessary. Slate over the old vent stack location.

3. Connect the remaining vent stack in the attic to the new stainless vent stack.

2. Cut out the old cast iron stack in the attic. Fix any rotten boards as necessary. Slate over the old vent stack location.

3. Connect the remaining vent stack in the attic to the new stainless vent stack.

Plumbing Stack Rules:

Builders and remodelers sometimes ignore this rule, however, plumbing vent stacks should never be on the front of a home.

NEVER PERMIT PVC pipe penetrations through a slate roof. PVC through a slate roof looks terrible (even when painted) and a heavy snow load can break them.

Rubber/plastic flashing kits should never be permitted on slate roofs. Standard plumbing vent kits deteriorate in 7 years. The best ones last 30 years, but why use any of these on a slate roof ... which may have a life expectancy of 100 or 150 years?

Copper flashing that wraps around and over the vent stack often causes condensation (as warm vent gases come in contact with the copper in the Winter). The condensation forms between the plumbing stack and the sleeve and then drips into the attic.

Solder streaks and lead that turns white over time look lousy.

All cast iron will eventually rust through, even vertical stacks.

Plumbing code now allows for a single 2" pipe to vent the entire house. However, due to proper sloping of vent pipes, most homes will require at least two plumbing vents.

Never let a plumber work on a slate roof.

Builders and remodelers sometimes ignore this rule, however, plumbing vent stacks should never be on the front of a home.

NEVER PERMIT PVC pipe penetrations through a slate roof. PVC through a slate roof looks terrible (even when painted) and a heavy snow load can break them.

Rubber/plastic flashing kits should never be permitted on slate roofs. Standard plumbing vent kits deteriorate in 7 years. The best ones last 30 years, but why use any of these on a slate roof ... which may have a life expectancy of 100 or 150 years?

Copper flashing that wraps around and over the vent stack often causes condensation (as warm vent gases come in contact with the copper in the Winter). The condensation forms between the plumbing stack and the sleeve and then drips into the attic.

Solder streaks and lead that turns white over time look lousy.

All cast iron will eventually rust through, even vertical stacks.

Plumbing code now allows for a single 2" pipe to vent the entire house. However, due to proper sloping of vent pipes, most homes will require at least two plumbing vents.

Never let a plumber work on a slate roof.

Two new vent stacks are shown in this photo, along with three of our V-5 permanent anchors. The two in background have their dark cast bronze cap covering them until their next use.